Hebei KeWang Rubber Products Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Innovations and Challenges in Bridge Expansion Joints

2025-07-18 13:19:19

Bridges are not just structures that span physical distances; they are lifelines for economies, communities, and the movement of people and goods. Among the numerous components that ensure a bridge's functionality and longevity, expansion joints stand out as critical elements. In this blog, we'll take a deeper dive into the world of bridge expansion joints, exploring recent innovations, persistent challenges, and the future outlook for these essential components.

The Ever - Evolving Landscape of Bridge Expansion Joints

Material Innovations

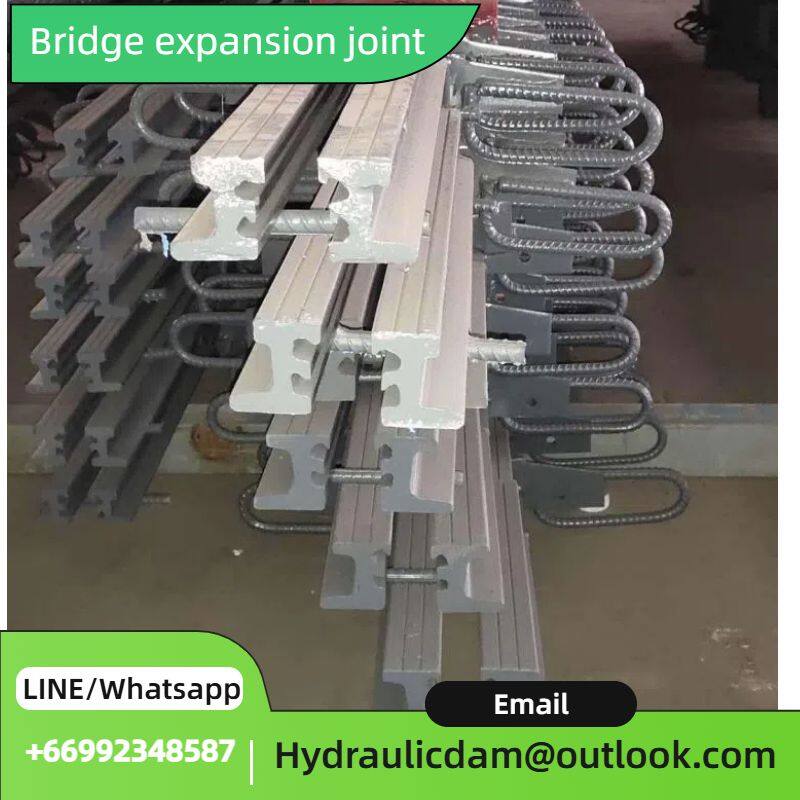

In recent years, there has been a significant push towards developing more durable and resilient materials for expansion joints. For instance, advanced polymers are being engineered to withstand harsh environmental conditions better. These polymers are not only more resistant to UV radiation, which can cause traditional rubber components to degrade, but they also offer enhanced flexibility and fatigue resistance. This means that expansion joints made from these advanced polymers can better handle the repeated stress of temperature - induced expansion and contraction, as well as the dynamic loads from traffic.

Another area of material innovation is in the use of corrosion - resistant metals. Stainless steels and other alloyed metals are being increasingly used in the construction of expansion joints. These metals can resist the corrosive effects of moisture, de - icing salts, and chemical pollutants, which are common in many bridge environments. By using such materials, the lifespan of expansion joints can be significantly extended, reducing the frequency of replacements and maintenance.

Design Innovations

Designers are also getting creative with the structural design of expansion joints. One such innovation is the development of self - cleaning expansion joints. These joints are designed with unique geometries and materials that prevent the accumulation of debris, dirt, and water. For example, some self - cleaning joints have sloped surfaces or hydrophobic coatings that cause water and small particles to slide off easily. This not only helps in maintaining the proper functioning of the joint but also reduces the risk of damage caused by trapped materials.

Smart expansion joints are another exciting development. These joints are equipped with sensors that can monitor various parameters such as temperature, movement, and stress levels. The data collected by these sensors can be transmitted in real - time to a central monitoring system. Engineers can then use this data to predict when maintenance or replacement might be required, allowing for more proactive and efficient bridge management.

Persistent Challenges in the Realm of Expansion Joints

Installation Complexity

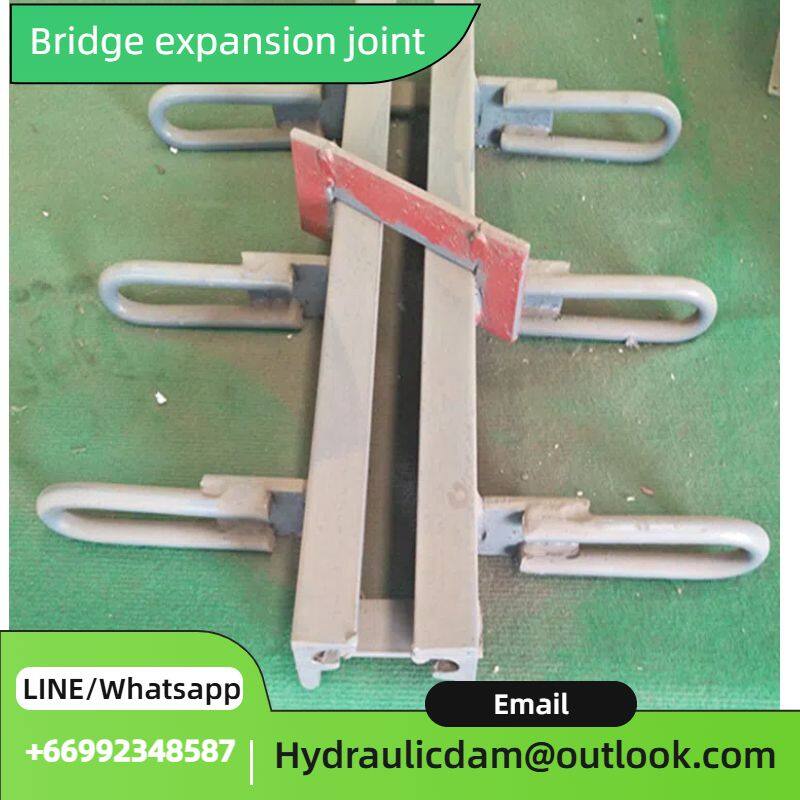

Despite all the advancements, installing expansion joints correctly remains a challenge. The process requires a high level of precision. For example, the alignment of the joint components, such as in modular joints, needs to be exact to ensure smooth movement and load distribution. Any misalignment can lead to uneven wear, premature failure, and an uncomfortable ride for motorists. Moreover, the installation process often needs to be coordinated with other aspects of bridge construction, such as the placement of decking and the installation of railing systems, which can add to the complexity.

Compatibility Issues

With the wide variety of bridge materials and construction techniques available, ensuring compatibility between the expansion joint and the rest of the bridge structure is crucial. For instance, if an expansion joint is made of a material that has a different coefficient of thermal expansion compared to the bridge deck, it can lead to stress concentrations at the interface. This can cause cracking, delamination, or other forms of damage over time. Similarly, the design of the expansion joint needs to be compatible with the overall structural design of the bridge, taking into account factors such as load - bearing capacity and expected movement patterns.

Tags: Expansion joint (Gap) in bridge, Bridge shrinkage joint, Bridge expansion joint